Newly hired (first-time) Analog Ink Technicians should not be faced with starting the job on their first day without having a solid understanding of what is expected.

An eye for color

You MUST have an eye for color.

If you somehow got hired for the job but you DON'T have an eye for color, consider applying for a new job... NOW!

An eye for color is arguably the most valuable skill you should possess, so do something to improve your color matching awareness.

Josef Albers believes you can develop an eye for color! “For Albers, the fundamental building block of an art education was development of the capacity to see more acutely”.

Want to know how good your eye for color is? Take the Farnsworth-Munsell 100 HueColor Vision Test before starting the job. Take it again six months later to see your improvement.

Want to know how good your eye for color is? Take the Farnsworth-Munsell 100 HueColor Vision Test before starting the job. Take it again six months later to see your improvement. Or you can test your eye for color with this fun iPhone game - Specimen.

You may find the book An Eye for Color, by Olga Gutierrez de la Roza, of particular interest. As she says, “Developing your own eye for color does not necessarily come naturally. Just as an athlete trains his body for a marathon, so must you train your eye and mind to perfect your use of color.” Her book aims directly at helping you do just that!

Open to change

“Everything changes and nothing stands still” (Heraclitus).

You must be open to change. You will need, the ability and willingness to be open minded with not only the way you do things but the way you think about things.

You must be adaptable. You will be expected to follow specific formulas that have been developed over years. AND you will have to trouble shoot when what you created doesn't work the way it should.

Be enterprising. Opportunities for new mixes/formulas are at your fingertips.

Frugality

“Work Off” - Extra unused ink left over from a job.

For many reasons, ink goes unused and gets left behind: sitting unnoticed in a corner, tucked away in a closet, lost under a shelf, or unused after a customer changed an order… That ink is considered a financial loss to your boss.

For many reasons, ink goes unused and gets left behind: sitting unnoticed in a corner, tucked away in a closet, lost under a shelf, or unused after a customer changed an order… That ink is considered a financial loss to your boss.

But what if YOU can work it in to your current job instead of ordering new ink? Who do you think is going to get noticed (in a good way)?

By keeping an open mind and being willing to do just a little experimentation, you just might be able to save the company money. If you become known as someone who can use work-off, you will soon earn your place as the go-to tech when money and time get tight!

You do NOT want to be known as the tech that burns through ink, orders too much, or wastes unnecessarily. You MUST be frugal.

Recognizing value in suppliers

Your suppliers are one of your greatest assets.

If you should ever get stuck, they can suggest raw material alternatives and may even be willing to offer starting point formulations.

If you should ever get stuck, they can suggest raw material alternatives and may even be willing to offer starting point formulations.

Because they communicate with their customers - you and other ink technicians around the world - they may have heard of specific formulas that might be able to help YOU get started.

However, be wary of telling THEM too much information yourself.

If you find a very helpful supplier-agent who is willing to share with you, it is safe to assume that s/he will be equally loose lipped with your competitors!

If you find a very helpful supplier-agent who is willing to share with you, it is safe to assume that s/he will be equally loose lipped with your competitors!

That said, they KNOW what they sell and very likely can offer you assistance in a very meaningful way. Why waste time experimenting when the answers are on-tap and available for you in a virtual instant.

Think of it this way, if your computer at the office stops working, would you rather troubleshoot the problem for the next 4 hours or just call out the IT specialist (your supplier equivalent) to come reconnect the monitor cable for you?

Working to a deadline

If you are not used to working to deadlines, this may be a major area of stress for you.

You will be responsible for completing tasks under specific time constraints.

Even if you have all of the previous mentioned skills, if you cannot work successfully under pressure of time, you might find this job very challenging.

Take heart, you CAN and WILL improve!

I found these 7 steps to meeting deadlines provided so succinctly by sitepoint.com very helpful:

- Get Clarification (be clear on expectations)

- Come to Agreement (put it in writing when necessary)

- Work Backwards (create milestones in reverse)

- Break it Down (each task = individual action)

- Give Yourself Extra Time (flexibility to shift time as needed)

- Go Step-by-Step (focus on the individual task)

- Keep Everyone in the Loop (regular status updates)

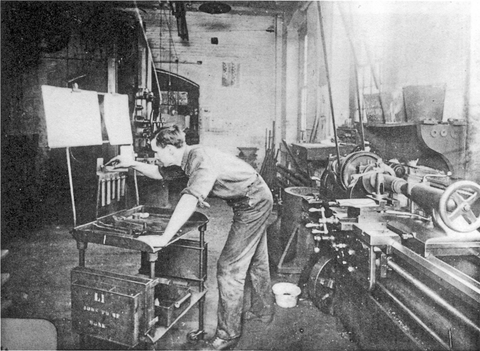

Knowledge of the press environment

When things don't work the way they are supposed to, you can help solve the problem.

The analog ink tech absolutely must be familiar with the press environment.

Just like you may need to call on the supplier for assistance with a starting formula, you might actually be called on by the PRINTERS to figure out why the color is all-of-a-sudden not printing the way it is supposed to.

Just like you may need to call on the supplier for assistance with a starting formula, you might actually be called on by the PRINTERS to figure out why the color is all-of-a-sudden not printing the way it is supposed to.

As Bob Peterson (an Inplant Technician) suggests, “All ink techs should spend time working in production with the inks they will ultimately be working with. This will provide them with the understanding of the process and time it takes to produce the product. Additionally, the tech should spend a substantial amount of time in the printing press room getting to know the equipment, and the variables that contribute to potential problems.“

Being familiar with the printing press may help you provide THEM with an answer.

You need to be familiar with "how conditions on press affect the performance of ink sets” (Chuck Koehler - a Technical Service Representative).

Substrate Variations

Not all substrates are created equal!

Prior to starting the job, you need to be aware of the various print media types utilized in the commercial printing industry. A few of the most common substrate families an ink tech might need to prepare ink for are: self-adhesive, banner, film, fabric, mesh, paper-aqueous, paper-solvent, photorealistic-low temperature, and synthetic paper (to name but a few).

If, for example, you do not know that paper-aqueous substrate is NOT compatible with solvent inks, you might provide the client with a truly INCOMPATIBLE product to their specific need!

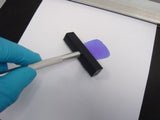

Use as close to the same methods of ink delivery that will be used in the pressroom - be they meyer rods, chrome anilox rollers or ceramic anilox rollers to mimmic the delivery of the ink to the substrate for best results.

Organizational Skills

Have you ever lost time searching around your desk for a particular file, piece of information,… your keys?

As Jill Lee (author of Importance of Organizational Skills in the Workplace) puts it, “If you are well-organized..., you can save hours during the week and significantly increase your productivity and decrease your stress level.”

As Jill Lee (author of Importance of Organizational Skills in the Workplace) puts it, “If you are well-organized..., you can save hours during the week and significantly increase your productivity and decrease your stress level.”

As an Ink Tech, you really need to keep your work space organized. Not only will this help you keep from mixing up your various projects, it will also help you earn your superiors’, co-workers’ and clients’ respect.

Getting back to #5, staying organized will aid you in your time-management and, your ability to reach your deadlines without too much stress!

How dirty should an ink technician expect to get

Getting ink on your hands is almost unavoidable!

Getting inked is a likelihood, but for some, it could be a daily inevitability!

Getting inked is a likelihood, but for some, it could be a daily inevitability!

There are many hand cleaners out there, some work better than others.

Here at INK SOLV 30, we like to think that because we were originally developed in 1937 to remove ink stains specifically for workers in the printing industry, we are the best of the best. We'll send you a free sample to prove it to you!

We are tired of being the industry's best kept secret. It is time to let this little hand cleaner out of the proverbial bag!

INK SOLV 30 would like to send you a free sample of our super strength industrial hand cleaning powder specifically formulated to remove the most stubborn dyes and printing inks.

INK SOLV 30 has an extremely long shelf-life; unlike goops and lotions that will degrade and separate over time, INK SOLV 30 maintains its cleaning power for years. You will NOT be disappointed!

INK SOLV 30 has an extremely long shelf-life; unlike goops and lotions that will degrade and separate over time, INK SOLV 30 maintains its cleaning power for years. You will NOT be disappointed!

Even if you think your current hand cleaner works moderately well, we'd like you to accept our challenge! With just a teaspoon of our product, mixed with enough water from your faucet to form a paste, there isn't another cleaner around that can remove ink from hands as well as INK SOLV 30!

In closing, as Tony Jimenez (an Ink Room Manager) put it so simply, “Knowledge about the industry… Is a must”! We believe that extends to knowing about the cleaners you use too! Go on, give us a try!

Because you shouldn't have to wear your work home!

Leave us a comment, we'd really like to hear your input!

*Data for this article was collected from Ink Technicians, Ink Room Managers, InPlant Technicians, Application Engineers, Technical Service Reps, and Process Supervisors through an online survey developed and produced by INK SOLV 30, the printing industry’s hand cleaner of choice since 1937.

**Special thanks to Tony Jimenez, Kayle A. Moss, Bob Peterson, Charles (Chuck) Koehler, and Mark Maharaj for their additional and insightful input which they so generously provided.